Load Testing and Method of Installation

Manhole covers and gully grates installed should meet the requirements of the European Standard BS EN 124. This applies to all situations, on and off-road and to all materials.Products designed to BS EN 124 are grouped and classified depending on their place of installation. It is the responsibility of the engineer to ensure that the correct product is specified.The appropriate class of manhole top or gully top to be used depends upon the place of installation.The selection of the appropriate class is the responsibility of the Engineer and Designer, Where there is any doubt of load bearing capacity, the stronger class should be selected.

FIBROCAST FRP/GRP/COMPOSITE products are tested for 2.5 tons, 5 tons, B125 (12.5 tons), C250 (25 tons), D400 (40 tons) and E600 (60 tons) class load bearing and permanent set as per BS EN 124, IS 1726 and AASHTO. BS EN 124 is a testing code worldwide for Manhole Covers in Cast iron, Ductile Iron and other materials also. Permanent Set is a multiple loading test to determine the permanent deformation in cover after multiple loading within a short time as specified in the code.

Installation Procedure

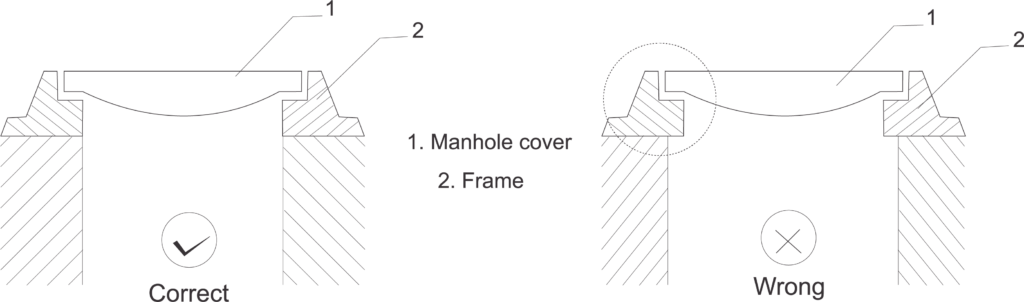

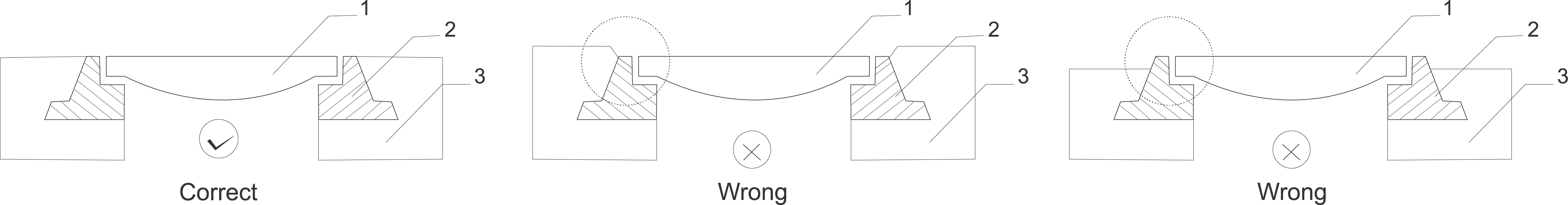

- Clear opening of the frame should not be smaller than that of the chamber. Make sure the top level of the frame should match the ground level.

- Prepare concrete bed considering height of the frame

- Frame should be embedded in minimum M-20 grade concrete

- In case a section of frame is not supported with solid ground, a RCC beam (Min M-20 grade) not less than 100mm in height must be installed for resting bellow unsupported section.

- A frame should be allowed to set in concrete for a minimum time of 48 hrs. before its use.

1. Manhole Cover 2.Frame 3.M-20 Grade Concrete